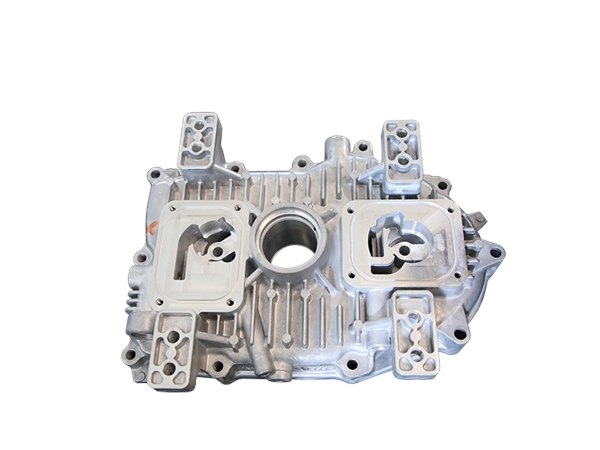

Product Detail:

MOQ: 500kg

Material: Aluminum alloy

Lead Time: 25 days for mold. Production depends on quantity

Tolerance: High Precision Machining Offered.

JPR Model is a professional company designing and producing rapid prototyping, cnc machining parts, sheet metal parts and aluminum casting parts. With international advanced equipment and experienced technical team, our company can meet or exceed your expectation in precision, appearance, performance and service life. With the goal of helping our customer to save their development time and cost, we will provide one-stop service to make sure you are satisfied with all the details.We provide micro machining and OEM ODM cnc machining service.

Die cast aluminum is a kind of aluminum wherein metals are molted under high pressure in the mold cavities. In the die casting process, the metals are hardened and the desired shapes are produced. Aluminum die casting can be made with the use of either hot chamber or cold chamber process

Advantages of Aluminum Die Casting Parts

· lightweight;

· high dimensional stability for complex shapes and thin walls;

· good corrosion resistance;

· good mechanical properties;

· high thermal and electrical conductivity;

· retains strength at high temperatures.

The aluminum die-cast auto parts series is one of the traditional products of JPR Model. we manufacture car engine bracket, valve rocker arm bracket, cylinder head cover,flying wheel housing,engine enclosure case,pipe fittings etc. Our die casting engineer and worker will assist you with aluminum die casting prototypes, die cast tooling, machining of die casting parts and finish the surface of many kinds of die cast aluminum parts. Our main casting material is mainly aluminum A356, 380, 319 with T4,T5,T6 heat treatment process. JPR Model would like to receive your drawings, samples, pictures and ideas for inquiry, and we also would like to send our parts as samples for your reference if you need.