The EDM Micro-hole processing machine can process various conductive materials such as stainless steel, quenched steel, hard alloy, copper, aluminum, etc. It can process a diameter of φ0.3-3mm, the maximum depth-to-diameter ratio can reach more than 300:1, and the processing speed per minute It can reach 40-60mm and can be penetrated directly from inclined or curved surfaces. The X, Y and Z axis of the worktable are equipped with grating digital display, and the Z axis has the function of depth fixation. Micro-hole electrical discharge machining is often more economical to used for hardened materials. Sinker EDM would be more expensive and is typically 10 times slower than micro hole EDM.

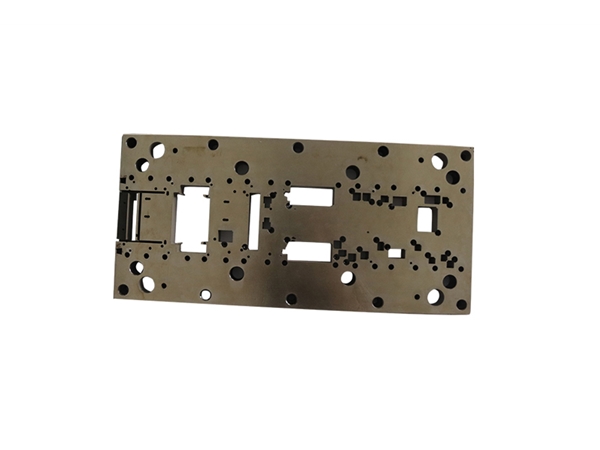

Much of our wire EDM services involve micro machining and small parts.JPR Model is fully capable of doing low volume prototype micro EDM work, as well as standard wire EDM work. But we also welcome long production runs numbering in the tens of thousands. Many of our customers seek our input on how to design their products for manufacturability. By working with the customer, and applying our knowledge of manufacturing and wire EDM processes, we can often help engineers design a product that functions well, looks good, and is less expensive to build. This has helped many of our customers be more competitive in the market place.

If you are looking for micro-hole electrical discharge machining service, contact us for RFQ. We will quote as soon as possible as we receive drawings.